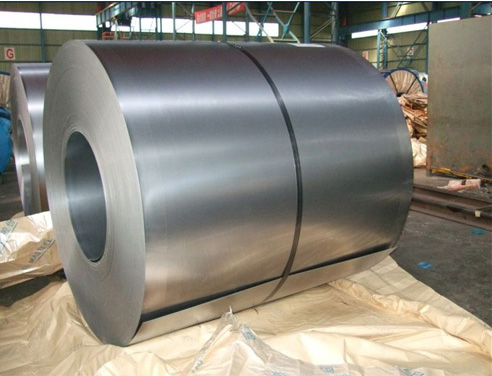

Cold rolled sheet

In order to reduce the cost of raw materials and extend the production chain of the enterprise, the company invested more than 188 million yuan to build a 20-roll cold-rolled precision sheet production line, covering an area of 4,500 square meters. The production line uses hot-rolled coils as raw materials, and after pickling and cold-rolling, it can produce cold-rolled hard steel coils, cold-rolled silicon steel sheets, and cold-rolled stainless steel sheets.

1200mm twenty-high single-machine reversible cold rolling mill

1.1 Main use:

For the production of cold-rolled galvanized substrates, tin-plated substrates, stainless steel and other precision cold-rolled strips.

Unit technical specifications

2.1 Ingredients Specifications:

2.1.1 Blank material: low carbon steel, stainless steel, silicon steel

2.1.2 Thickness of billet: low carbon steel 0.8-3mm, stainless steel 0.4-2mm, silicon steel 0.8-3mm

2.1.3 Width: 800-1050mm

2.1.4 Inner diameter of coil: 610mm

2.1.5 Maximum outer diameter: 1850mm

2.1.6 Maximum roll weight: 20t

2.2 Finished size:

2.2.1 Thickness: 0.15-0.8mm

2.2.2 Thickness accuracy: 0.2mm in steady speed section